| We "tag" zerks with different colored caps to communicate that this zerk requires FOOD GRADE GREASE, not machine grease. |

| This zerk requires MACHINE GRADE GREASE, not food grade grease. We code these zerks with black caps. |

| We place desiccant bags into control boxes to keep electrical contacts and components dry. |

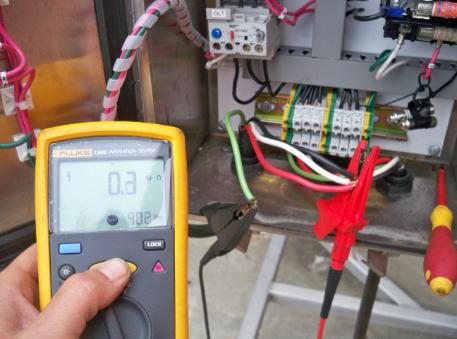

| DI-ELECTRIC BREAKDOWN TEST This motor (or the wires between its This motor (or the wires between its starter and its power connections) that when there is 482 V DC applied to the conductors, the insulation breaks down and allows current to pass to ground with just .3 ohms of resistance. We need to isolate this problem before the motor is damaged. In most cases, this is caused by a fork lift driving over a power cord or a motor with damaged windings. |

| MOTOR BALANCE TEST One of the tests we perform on motors is an ohms test to determine balance of windings. This test was performed again at the motor terminals after dis-connecting the power cord. |

| This zerk requires FOOD GRADE GREASE, not machine grade grease. We code these zerks with white caps. |

| Bad electrical junciton box seal allowed water to electrical connections which caused premature failure of this crusher motor. |

| This machine literally caught fire because of a lack of maintenance. |

| cord seal and strain releif failure causes electrical issues. |

| Hey... if we put a hanger on the other side of this control, the cord could would be free to hang straight down. Hmmmm. |

| Unfinished work: This edge is as sharp as a knife! |

_________________________________________________________________________________________________________________________