with the unit allowed the auger to spin at a minimum of 5

about 10 Hz.

In other words, the customer was running the equipment as

itself based on inefficient motor usage.

Proposed solution:

WSC was able to determine that the customers target auger

rate was between 1 and 4 rpm. The most practical way to

achieve the target was to change the drive and idle gearing

We replaced the drive sprocket with a smaller sprocket.

We replaced the idle sprocket with a larger sprocket.

Result:

The customer now has an operating range of 0 to 4.75rpm.

Benefits:

The motor operates inside of its intended speed range.

The VFD operates closer to its intendended speed range.

The customer has better adjustability inside of his intended

production range.

about 10 Hz.

In other words, the customer was running the equipment as

itself based on inefficient motor usage.

Proposed solution:

WSC was able to determine that the customers target auger

rate was between 1 and 4 rpm. The most practical way to

achieve the target was to change the drive and idle gearing

We replaced the drive sprocket with a smaller sprocket.

We replaced the idle sprocket with a larger sprocket.

Result:

The customer now has an operating range of 0 to 4.75rpm.

Benefits:

The motor operates inside of its intended speed range.

The VFD operates closer to its intendended speed range.

The customer has better adjustability inside of his intended

production range.

| Power Transmission |

Benefits:

The motor operates inside of its intended speed range.

The VFD operates inside of its intended speed range.

The customer has better adjustibility inside of his intended

production range.

The motor operates inside of its intended speed range.

The VFD operates inside of its intended speed range.

The customer has better adjustibility inside of his intended

production range.

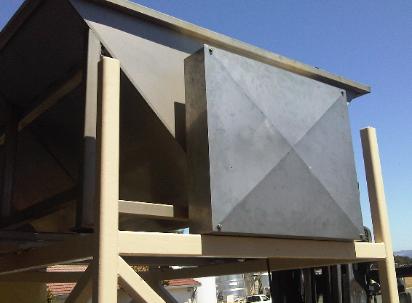

| Before: auger turns too fast; speed range is not optimized for the customer. |

| During: Determine what sprockets are needed to hit the customers production range. re-design gear enclosure, generate a cad model. |

| After: We have hit the customers required production range of 1 to 4.75 RPM. |

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________