| This is a press door from a Diemmi AR80 MSC press. The seal on this door is an inflateable bladder. If this seal is compromised, the press will not function. |

| The idle side of this assembly is supported by a teflon bearing. Its a wear part. If the part is not checked and replaced periodically, the bearing will wear and eventually damage the beater bar bearing surface. This beater bar has been damaged. A replacement beater bar is over $3,000 For this project; WSC used a jig to support and spin the beater bar. after the damaged bearing surface was true and round, we supplied a few custom teflon bearings with a slightly smaller inner diameter. |

we've got the experience to inspect, repair or replace your press blader. |

| Delta E2 destemmer with compromised cage drive sprocket. Soon, this cage will stop turning.... as will production. Much of this damage was caused by mis-allignment between gears when closing the cage access door. Is your team aware of these potential pit-falls? |

| Delta E2 destemmer with worn sprocket teeth. Step 1: Chain stretches or loosens Step 3: sprockets begin to wear. If corrective action is taken at step 1, the repair would be to tension or replace the chain. If action is taken at step 3: the repair is more costly because replacement parts are necessary. |

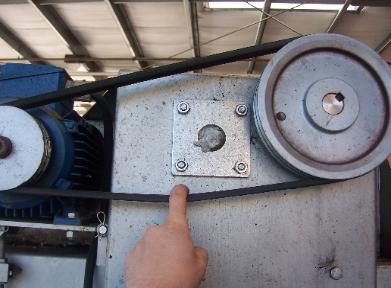

| Diemmi Kappa 25: Checking belt tension and condition. Do we have a spair belt? We might as well... its a wear part and it will be replaced sooner or later- |

| Zambelli destemmer crusher. bearing repair |

| We service all wine production equipment. This unit was ran into with the fork lift. The electrical enclosure and its internal components were damaged. WSC responded quickly. |

| Howard Fischer Press: small blower to evacuate the press runs at 175Hz! Provide, wire and program the VFD. |

|

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

| Get the most out of your equipment ! |